This article deals with the development that took place in the small agricultural farm since Harry Ferguson developed the tractor that bears his name and the tractor-hitching method known as the “Ferguson System.”

Agriculture worldwide is divided into two types of farms: the first is the small, family-owned farm, cultivating a privately owned plot of land of a size suitable for the family’s ability to work it by themselves. The second type, which has been growing in importance both globally and in Israel, is the specialized farm - large tracts of land managed by companies with significant investments in machinery and equipment.

This article focuses on the mid-20th century, during the transition from the use of draft animals - the main source of power on family farms - to tractors and equipment that replaced them, thus increasing productivity and easing the farmer’s workload.

In Israel, where most farmland is state-owned, a similar distinction developed according to the type of settlement: kibbutzim cultivated large tracts, and consequently, mechanization entered the kibbutz system much earlier than it did in the individual farms of the moshav. In the moshav, each farmer - with the help of his family - cultivated his own small plot in a mixed farm that included field crops, orchards, vegetables, a cowshed, and a chicken coop.

Until the late 1950s, horses or mules were the main sources of power in moshav farms, used for transport, soil cultivation, and operating implements such as mowers, rakes, and balers. (Part of the field produce was grown to feed these animals.) By the late 1950s and early 1960s, small tractors from Germany (Holder, Porsche) arrived in Israel, and there was even an attempt to manufacture tractors locally (“Zatut”). These replaced the work animals for transport, forage harvesting, and light fieldwork. Heavier tillage in the small plots of the moshavim was done by larger tractors, mainly Ferguson models, owned by a few individuals in each moshav - and very well suited to small farm conditions.

Harry Ferguson (1880–1960) was born and raised on a small farm in Ireland and personally experienced the physical hardship of farm labor. After studying mechanical engineering in the early 20th century, he sought ways to ease the burden of small farmers. At that time, agriculture was shifting from steam-powered to internal-combustion tractors, suited mainly to the vast fields of the United States. Implements that had once been pulled by numerous draft animals (such as a combine harvester pulled by 27 mules) were now pulled by tractors. The implement mechanisms were powered by their transport wheels, as were their lifting and lowering operations during fieldwork. In small fields, it was necessary for the tractor and implement to move forward in order to lift the implement during turns within the field.

Harry Ferguson set out to achieve the following goals:

1. Attach the implement to the tractor body so that the two form a single unit.

2. Enable easy lifting and lowering of the implement by the operator.

3. Increase the tractor’s wheel grip on the soil despite its light weight.

4. Operate the implement, when necessary, directly from the tractor rather than through its transport wheels, with engagement and disengagement possible from the driver’s seat.

5. Ensure that the pulling load on the tractor is steady and controlled, and automatically released in case of excessive strain.

6. Allow quick and easy implement changes so that one tractor could serve multiple tasks according to the farmer’s needs.

7. Let the farmer adjust the track width of the tractor wheels to match the spacing of the crop rows.

8. Offer farmers a wide range of implements, all easily attachable to the tractor.

9. Maintain post-sale contact with the farmer through regional service agents, providing special tools so that the farmer could service the tractor and equipment independently.

10. Enable tractor use under various environmental conditions - cold, snow, mud, etc.

11. Provide operator comfort: a comfortable seat, light pedals, easy steering, full control from the driver’s position over all necessary levers and gauges.

In 1936, Harry Ferguson, in partnership with David Brown, succeeded in producing a tractor that incorporated the “Ferguson System.”

What is the Ferguson System, and how does it achieve these goals?

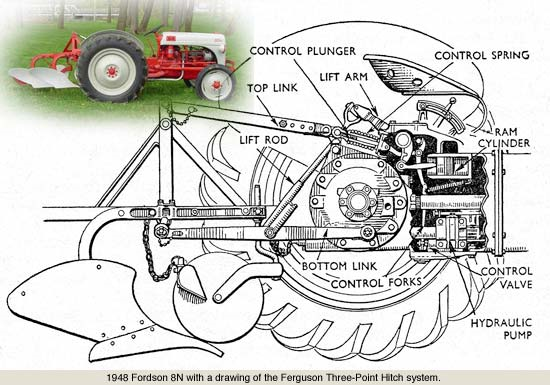

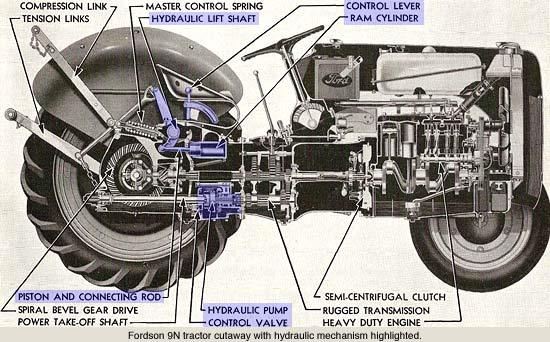

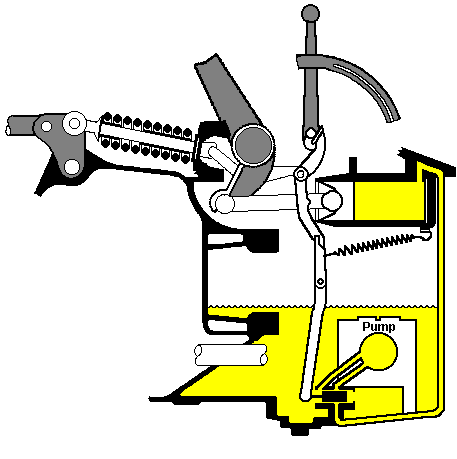

All implements are hitched to the tractor at three points: two lower arms, connected to the tractor body below the rear axle, pull the implement and raise or lower it as needed through hydraulic pressure. Above them is the third arm, connected to the tractor above the axle line and to the implement at a point roughly level with the vertical distance between the lower arms and the upper one. This forms a kind of parallelogram linkage, keeping the implement level to the ground even when lifted. The arms can be adjusted for height and length as needed.

The two lower arms do the pulling (for example, of a plow), while the soil resistance on the implement is transferred back to the tractor through the top arm in the opposite direction. In this hitching configuration, there is no danger of the tractor’s front end lifting under load; on the contrary - the load increases traction, improving the tractor’s grip on the soil and preventing slippage.

The hydraulic pressure used to lift the implement is generated by a pump immersed in the oil of the gearbox, and it also serves to operate additional equipment such as a front loader or a tipping trailer. The lifting and lowering of the implement are controlled by two factors: the operator - using a lever located to his right - and, during operation, a special mechanism that maintains a constant resistance of the implement on the top (third) linkage arm. When the implement encounters resistance greater than that preset by the operator, increased pressure is exerted on the top arm against the tractor. This, in turn, activates the mechanism to slightly raise the implement until the resistance returns to its previous level.

Implements requiring rotary motion for their operation-such as mowers or sprayers-receive it from the power take-off (P.T.O.) located at the rear of the tractor, rather than from the ground wheels as was previously the practice. Control of the P.T.O. connection is operated directly from the driver’s seat.

At the Ferguson factory, many implements were developed specifically for the needs of the small mixed farm, all designed to attach to the tractor using the three-point linkage system.

Below is a list of Ferguson-manufactured implements suitable for tractors of the TE20 series, many of which arrived in Israel together with the tractors in the early 1950s.

Seeding Equipment:

• Fertilizer spreader

• Trailed drill

• Potato planter

• Corn planter

• Sprayer

Tillage Implements:

• Blade plows

• Disc plows

• Reversible plow

• Subsoiler

• Various types of cultivators

• Various types of harrows

• Ridger

Auxiliary Equipment:

• Tipping trailer

• Rear box

• Manure loader

• Manure spreader

• Earth auger

• Scraper

• Tractor jack

• Wood saw

• Water pump

• Belt pulley for auxiliary drives

Harvesting Equipment:

• Potato digger

• Rear mower

• Underslung mower

• Reversible rake

• Twin rake

• Corn sheller

In 1938, Harry Ferguson moved to the United States, where, together with Henry Ford, he began producing tractors based on Ferguson’s system. This collaboration gave rise to the Ford tractors. In 1946, after a disagreement, Ferguson returned to England and established his own factory to manufacture these tractors, known as the TE20 series (Tractor England 20 h.p.), painted in grey. Production continued until 1956, when Ferguson’s company merged with Massey Harris of Canada, after which the tractors were painted red.

During Ferguson’s years in England, hundreds of thousands of tractors were sold worldwide-including to the United States-and several thousand arrived in Israel. The first models were powered by Standard engines running on kerosene (started with gasoline). From 1953 onwards, diesel-engine tractors-slightly more powerful-were imported, known locally as the Ferguson 28. Around the same time, Perkins replacement engines were also imported. Alongside the tractors came various compatible implements.

The tractors were well received, particularly in the moshavim (cooperative villages), thanks to their reliability, simplicity, and versatility.

These tractors became beloved among farmers worldwide, and in recent years, Ferguson enthusiasts’ clubs have been established in many countries-Denmark, the Netherlands, Germany, France, as well as England, Ireland, South Africa, and Australia. Affectionately called “The Little Grey Fergie,” members of these clubs restore tractors and hold regular exhibitions and gatherings.

At the Tractor Museum in Ein Vered, several such tractors are on display, along with a collection of implements that arrived with them.

Below are several online videos related to this topic.